What is Voltaiq?

Voltaiq is an enterprise battery intelligence platform that automatically collects, cleans, and harmonizes data from your test and production equipment for insight into the performance, quality, and health of every battery.

Plot data in seconds, get alerted to battery problems early, and find out what caused them with full traceability to upstream materials, processes, and production parameters.

Catch & fix battery

issues quickly.

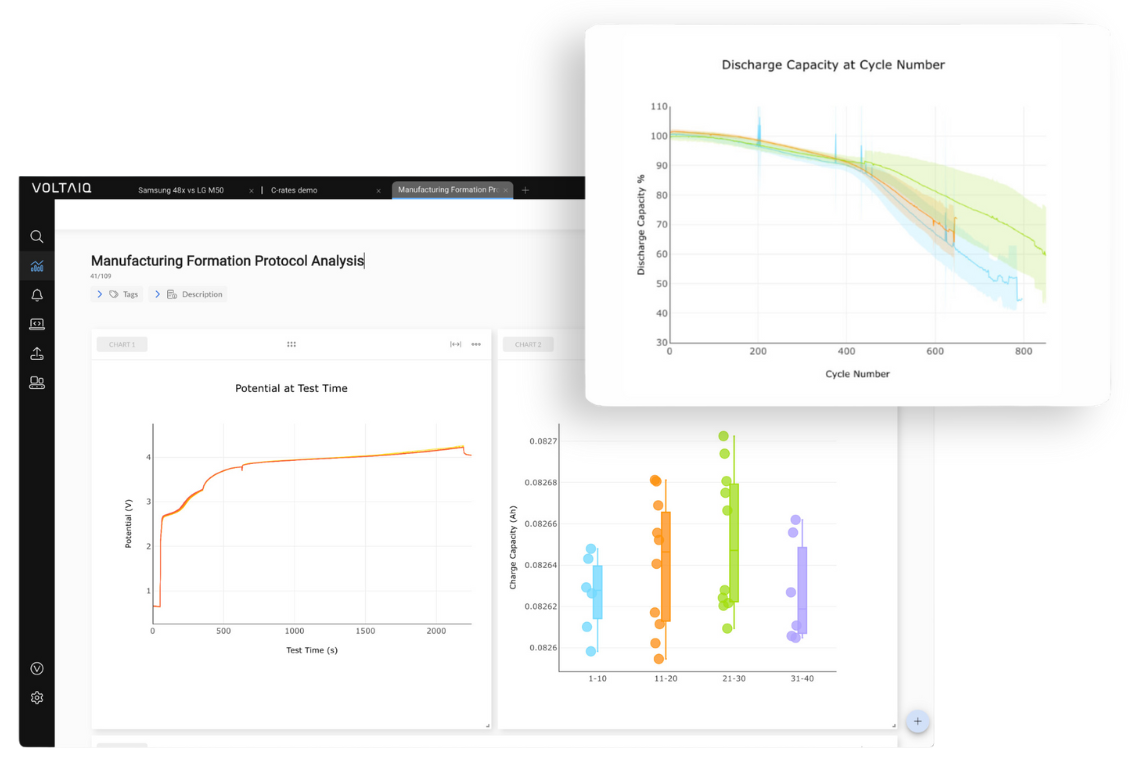

Voltaiq analyzes the charge-discharge “heartbeat” of every battery to catch anomalies weeks, sometimes months earlier than standard processes. This heartbeat reveals deep insights into the battery’s manufactured quality, lifetime performance potential, and overall health, easily accessible in one place.

How does Voltaiq work?

Voltaiq collects data from your equipment in real time, then cleans and harmonizes it into a common format for analysis and reporting.

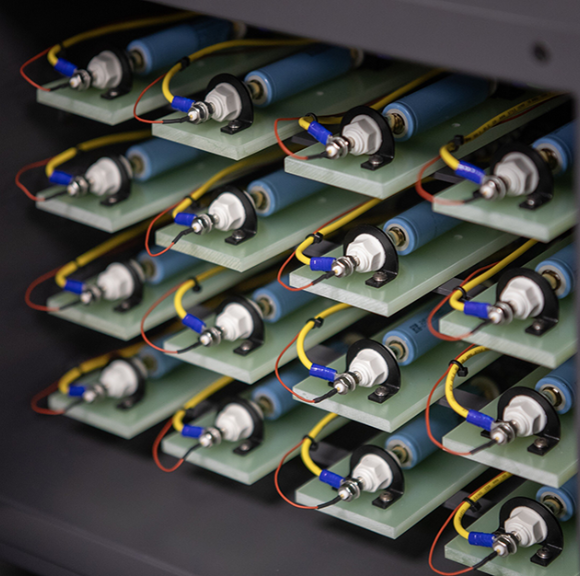

Automated Data Collection

Collect, clean, and harmonize data from any type of battery cycling equipment.

Automated Data input

Collect, clean, and

harmonize battery data from your test & production equipment.

Voltaiq collects raw data from your end-of-line, process equipment, materials tracking systems, and test lab cyclers, harmonizing it into a common format.

Feature, KPI, and Insight Extraction

Automatically extract the metrics and insights that matter.

Feature, KPI, and Insight Extraction

Automatically extract the key metrics and insights that matter.

Voltaiq uses decades of built-in battery expertise to automatically extract advanced electrochemical quality indicators for each battery, including internal resistance, dQ/dV peaks, and many more.

Traceability

Track every material, process setting, and build condition for each battery.

Traceability

Track every material, process setting, and build condition for each battery.

Voltaiq tracks all production materials, process settings, and build conditions for each battery, linking this information to a unique digital record, including materials lots, process lines, operators on duty, and more.

No-Code Analysis

Visualize essential data in seconds, compared to days using standard methods.

No-Code Analysis

Plot essential data in seconds, compared to days using standard methods

Perform advanced analysis in a few clicks, plotting time-series data, cycle metrics, battery KPIs, and comparing batch statistics. Includes voltage vs. capacity curves, DCIR vs. cycle number, pulse analysis, dQ/dV, and much, much more.Shareable Dashboards & Reports

Easily communicate quality issues and other key results for faster resolution.

Sharable Dashboards & Reports

Easily plot and communicate quality issues and other key results for faster resolution.

Easily find and share insights, while the integrated data science environment and platform APIs enable advanced processing, analysis and integrations.

Real time data access from your battery cycling equipment.

Voltaiq automatically collects data from your battery equipment in real time, cleans and harmonizes it into a common format, and surfaces the most relevant metrics for easy reporting.

Deep battery expertise to fast-track your program.

Decades of deep battery expertise, built into the platform and included in your Voltaiq subscription as consultative partners.

-

Accelerating product development

-

Supplier qualification program design

-

Factory ramp-up and optimization

-

Advanced analytical techniques (pulse analysis, dQ/dV, etc.)

The battery-specific solution to unify your digital infrastructure.

Voltaiq has decades of battery industry expertise and best practice built in, and integrates with all of the other vital systems you use to run your business.

How teams are using Voltaiq:

“Voltaiq helps us scale-up and run battery production efficiently, enabling my engineers to quickly pinpoint and resolve issues so we can keep moving forward.”

“With Voltaiq, we run a modern distributed battery program at a 70% lower cost. Most importantly my team can focus on battery engineering instead of data wrangling.”

Research & Development North America

“Voltaiq is such a game-changing solution. Eight years later and we’re still very impressed. I don’t understand why there is any barrier to adopting it. If you’re wondering if you can afford it, you can. You should be doing it. You’ll get more, better organized data with faster access. It’s a no-brainer.”

“Everybody uses Voltaiq. We’ve experienced much more rapid product development. We're able to see more of the data, more quickly, in more detail to make better decisions.”

"It’s the time savings. To do root cause analysis, FA, containment, and deployment of solutions. Also faster time for process development. What the ultimate comes down to is yield target and cost target. It all goes hand in hand."

Your battery data, secured.

Trusted by global industry leaders and Fortune 500 companies, Voltaiq adheres to the most rigorous security standards.

Our security-first approach ensures the safest environment for you to collaborate with your team and external partners on critical battery quality data.

Frequently asked questions

Considering Voltaiq for your battery program? Get answers to common questions about Voltaiq's battery intelligence and analytics platform.

Which industries benefit from Voltaiq?

From R&D and product development to full-scale production, Voltaiq provides insight into the performance, quality, and health of every battery with full traceability to upstream materials, processes, and production parameters.

Voltaiq is for any company that is developing or producing batteries, battery materials, or battery-powered products, and is collecting battery charge and discharge data in the process.

Voltaiq works with companies across the battery lifecycle that are:

- Performing battery R&D

- Developing battery-powered products or systems

- Evaluating battery suppliers

- Scaling up production

- Concerned about warranty or safety issues

- Experiencing delays in product launches

Voltaiq’s customer base includes companies that make:

- Electric vehicles (including both the flying and driving kinds)

- Consumer electronics

- Medical devices

- BESS

- Battery packs

- Battery cells (everything from lead-acid to lithium-ion and next-gen chemistries)

- Battery materials

- Battery components (e.g. separators)

- And much more

How does Voltaiq accelerate battery production scale-up?

Voltaiq speeds up the many iteration cycles you need to dial in processes and tolerances when ramping up battery production, from lab to pilot or pilot to full-scale manufacturing.

Voltaiq alerts you to battery production anomalies within hours of final assembly using end-of-line formation cycling data, catching production problems days or weeks sooner than standard QC. Issues can be traced back to upstream materials and processes to quickly find the root cause of an issue. Reports and dashboards make it easy to share your findings and fix the issue immediately.

How does Voltaiq improve battery production yield?

Voltaiq alerts you to battery production anomalies within hours of final assembly using end-of-line formation cycling data, catching production problems weeks faster than standard QC. Trace issues back to upstream materials and processes to quickly find the root cause of an issue and correct it.

How does Voltaiq help prevent recalls?

Voltaiq helps identify and address quality issues early in the battery development and production process, reducing the risk of defective products reaching the market.

Does Voltaiq work for R&D teams?

Yes. Voltaiq helps R&D teams shorten development cycles and achieve milestones faster. The sooner you start dialing in materials and process tolerances, the lower your costs will be as you scale. We recommend reaching out to Voltaiq once you’re running 50 or more cell cycling channels, or 10 or more channels for module/pack testing.

Most R&D teams onboard with Voltaiq’s Essential Tier (starting at $5k per month) and scale their Voltaiq subscription as they grow.

Can I customize Voltaiq to fit my processes?

Yes. Voltaiq includes configurable no-code dashboards, customizable metric collection and computation, a built-in battery data science environment, and customizable APIs to support any systems or processes that may be unique to you or your organization.

How does Voltaiq compare to our existing internal and enterprise tools for battery analysis?

Voltaiq integrates with your existing tools to do battery data analysis, faster, easier, and with greater insight. Made by and for battery engineers, Voltaiq has industry best practices built directly into the platform and is production-proven with dozens of leading global companies for over a decade.

Voltaiq comes standard with a comprehensive set of battery-specific metrics, visualization tools, and data management features built in. If your existing tools have gaps around functionality, data latency, integrations, scalability, security, and compliance, Voltaiq can support you at a fraction of the cost of maintaining an internal solution.

Can Voltaiq integrate with my existing tools and workflows?

Voltaiq is designed to work with and improve what you already have in place. With full API connectivity and native integrations, Voltaiq connects with your existing tools whether they were built in house or are provided by other vendors.

Voltaiq integrates with LIMS, MES, and spreadsheets to analyze your material and process data in parallel to electrochemical data. JMP, Minitab, Matlab, PowrBI, and Tableau users can use tools they already know to access a unified, comprehensive source of cleaned, searchable battery data with all of their key electrochemical metrics already extracted.

What kind of support does Voltaiq offer?

Voltaiq’s support team is made up of experienced battery engineers to understand your needs and proactively guide you to take full advantage of the platform. These battery engineers assist with onboarding, training, and ongoing support to ensure customer success.

Professional and Enterprise tier customers have access to assigned battery engineers, prioritized support, business reviews, consultative workflow and analysis development, and customized user enablement.

What ROI can I expect?

Voltaiq is the only battery analytics platform with proven success at enterprise scale and has been in production at global companies for over a decade.

Results include:

- Up to 70% reduction in cost of test programs compared to legacy practices

- On average 50% faster quality issue identification in qualification and validation testing

- On average 1,000x return on investment in first year of gigafactory ramp-up

- Over 50% faster yield ramp in gigafactory scale up

How does Voltaiq's pricing work?

Voltaiq offers three SaaS product tiers: Essential, Professional, and Enterprise. Each tier offers different levels of functionality and support.

Essential (starting at $5k per month, billed annually) is designed for day-to-day battery data analysis and management, ideal for smaller battery programs and standard analysis workflows.

Professional is an enhanced offering for organizations requiring more powerful automation and advanced configurability.

Enterprise offers the full suite of features and the highest level of support for manufacturers and OEMs.

Pricing is dependent on your specific application, annual data volumes, and service needs (e.g. custom integrations or development of new analytics). Please request a demo to connect with our sales team and we will help determine the appropriate tier for your use case.

What happens after I request a demo?

After you request a demo, you will book time with a member of Voltaiq’s sales team. In this initial call we will give you an in-depth overview of Voltaiq’s solution and talk about the problems your organization is hoping to solve.

From there we put together an in-depth demonstration for your specific use case and work together to select the best product tier to meet your needs.

Better business decisions start with a better understanding of your batteries.

Ready to get started?

-1.png)