Lyten achieves over 90% yield with Voltaiq.

Lyten, a leading developer of lithium-sulfur batteries, chose Voltaiq as its digital platform infrastructure to enable rapid growth. Celina Mikolajczak, an industry veteran with experience at Tesla, Uber, and QuantumScape, shares why Lyten chose Voltaiq over building internally, citing headcount efficiency, equipment integrations, and data security as key factors.

The Problem

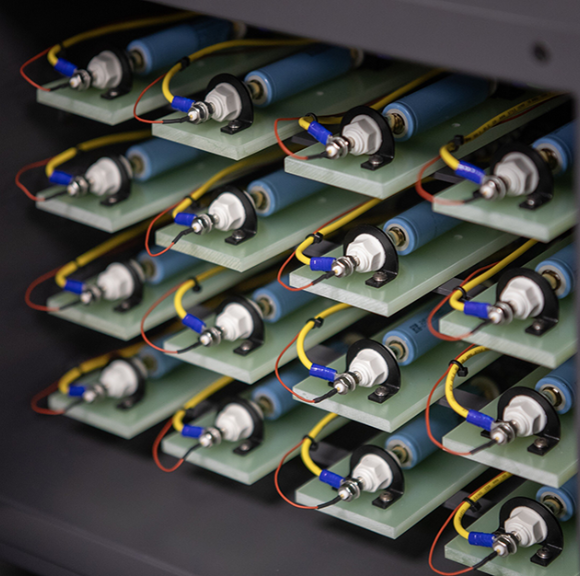

As Lyten grew, performance and quality testing across development and production generated increasing volumes of data across several different types of equipment. Drawing engineering insights from this data, and even basic data management, was getting complicated quickly. Lyten had a choice–either spin up a large team tasked solely with writing scripts to pull data from cyclers and put it in reports, or purchase an integrated solution.

The Solution

The decision came down to three factors:

- Dedicating headcount to core competencies

- Integrations with industry-standard equipment

- Data security

Dedicating headcount to core competencies.

When it came to resource allocation, Lyten chose to focus on R&D and their core business of cell manufacturing.

“When I came to Lyten, we've got a lot of data, we've got a lot of work to do here. There is no way that I've got a headcount allowance that lets me create our own software product. And there's no reason to. If my boss is going to give me a headcount, I'm going to spend it on R&D work,” says Mikolajczak.

“I know what a homegrown system takes to maintain. We're cell makers. We're not software makers. So it makes all the sense in the world to go and purchase Voltaiq.”

Integrations with industry-standard equipment.

Lyten’s data, like many companies in the battery sector, is generated by a range of cycler versions and manufacturers.

An internal solution would require a team to manage and maintain the system anytime a hardware vendor made a minor software update.

Mikolajczak explained her thought process. “ What's the headcount going to be to deal with every time Arbin changes their software slightly? Or when Neware or Digitron or Maccor does something? It's all different. What's it going to take to maintain that, and to maintain the software system?”

-2.png)

IP and Data Security

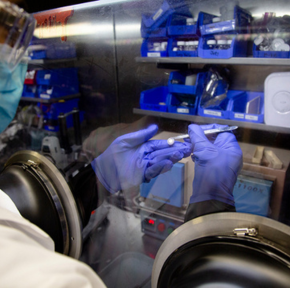

As a global leader in a new battery technology, IP and data security are paramount for Lyten.

“We're doing new technology which means that we have a lot of IP involved here. So then the question becomes how do you maintain that data security and integrity across these systems?”

With an in-house team, this becomes an issue. “Do I have a guy? That specializes on our data security for our cycling data, or do I rely on a system that I've purchased where there's a bunch of guys who've worked this out and who continue to look at this?”

Impact

Lyten is now consistently surpassing 90 percent yield from its automated battery production line, confirming the manufacturability of its lithium-sulfur battery utilizing a sulfur cathode and lithium metal anode. The conversion of lithium-ion equipment to produce lithium-sulfur batteries in Lyten’s pilot facility required 6 weeks and less than 2% of the total capital cost. This confirms Lyten’s ability to rapidly scale by converting existing Li-ion gigafactories to lithium-sulfur with minimal cost and time.

Lyten has credited Voltaiq with helping speed up the innovation and quality improvements of their cells, establishing themselves as a global leader in lithium-sulfur technology. “Cell making, cell development is all about the data. It only goes as fast as your researchers can look at the data, take it in, analyze it, and then move forward. Same thing on your manufacturing line,” says Mikolajczak. “ I have data wizards who specialize in, really digging into the data. But, I have a lot of other engineers who want just a simple look at what's happening with their cells. When you make that easy to get, it just speeds up the innovation and the quality improvements that you can make on your cells. It speeds everything up.”

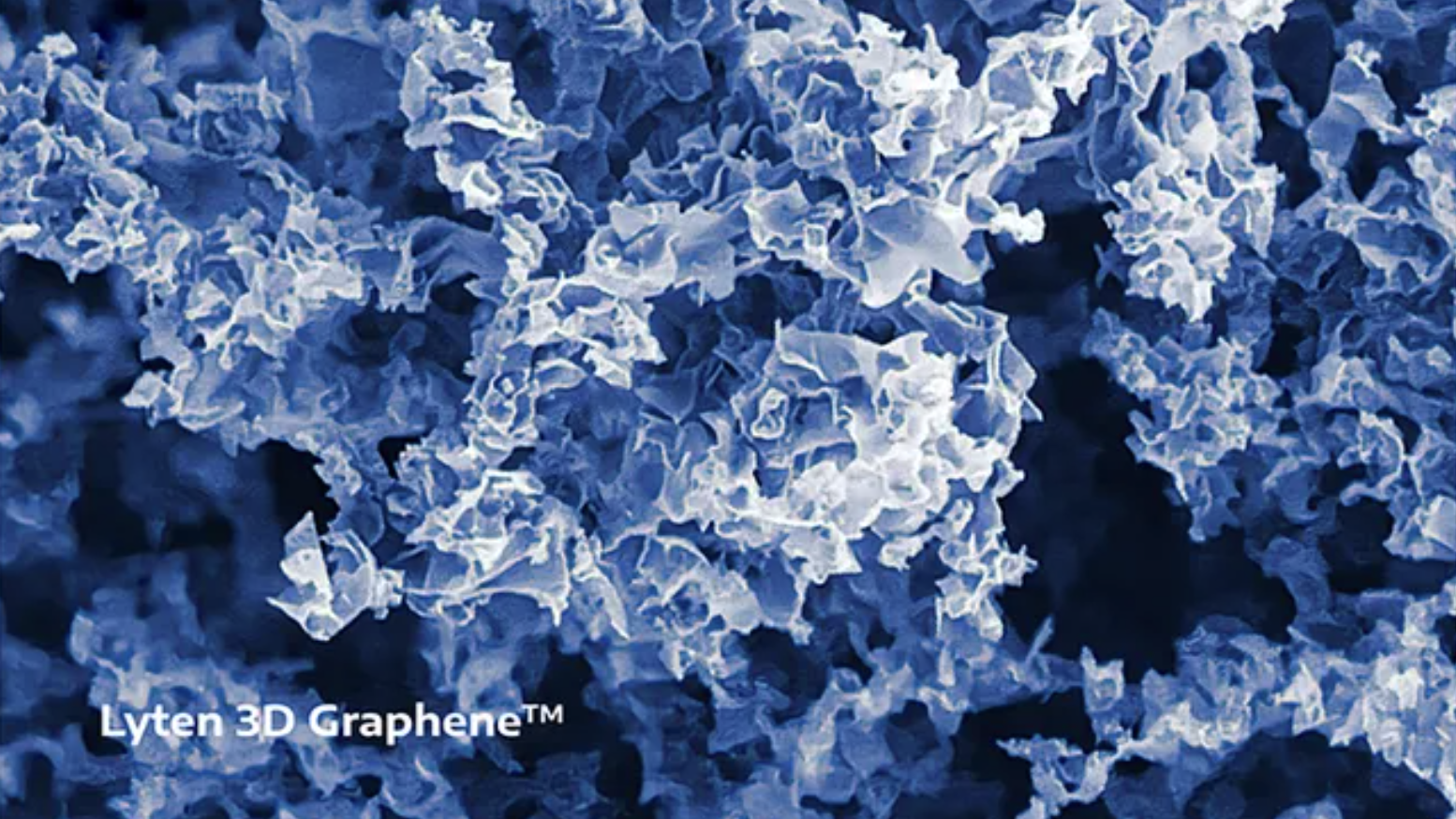

About Lyten

Lyten is developing lithium-sulfur batteries, a next-generation technology with the potential to truly electrify everything. This technology, with its high energy density, low cost, and simplified, geopolitics-agnostic supply chain, has the power to revolutionize cell manufacturing.

Lyten cells can power everyday vehicles and heavy-duty applications like trucks, where their high energy density allows for significant battery pack weight reduction, with applications in the satellite industry, where weight and low-temperature cycling performance are critical, highlighting the versatility of their lithium-sulfur battery technology.

"We're cell makers. We're not software makers. So it makes all the sense in the world to go and purchase Voltaiq.

It speeds up the innovation and the quality improvements that you can make on your cells. It speeds everything up.”

Better business decisions start with a better understanding of your batteries.

Ready to get started?