The last decade has seen a significant expansion in the application of advanced data analytics techniques, namely machine learning (ML) and artificial intelligence (AI), across a wide range of industrial sectors. Results to date have been mixed, but there remains great hope in the transformational potential of ML and AI, as well as broad agreement that these technologies will have a major and positive impact as they mature.

The battery ecosystem has taken notice, and is eagerly trying to jump on board the ML/AI train. There is increased awareness throughout the industry that batteries are complicated, and that data analytics are key to maximizing their business value, with proven use cases accelerating time to market, minimizing product risk, and optimizing operational performance. As today’s headlines are awash with stories of intelligent algorithms changing the world, it’s no surprise that executives across a range of battery-powered businesses see ML and AI as a panacea solution to their battery headaches. Predict battery failure down to the minute, diagnose state of health (SOH) to three decimal places, identify the next breakthrough battery material — all of these are things that companies believe ML and AI will solve for them. And maybe they will.

The directive gets issued from the executive suite, “We need to use ML on our batteries!” It gets passed down to engineering, and engineers like building things themselves. As such, these days we see a lot of job posts for companies seeking to build an in-house, from-scratch battery machine learning function, that look something like this:

Seeking battery data genius / systems architect / data engineer / data scientist

Qualifications:

- Highly developed analytical and interpersonal skills, with proven ability to locate disparate data sources across an organization and combine them to develop an industrial-quality predictive model

- Background in data science, machine learning, and engineering energy storage technologies

- 5+ years experience building and deploying enterprise-class data pipelines

- Experience with battery test equipment and data formats

- Experience in Pytorch, Tensorflow, Keras, Numpy, Pandas, Scikit-Learn, Tableau, Microsoft Excel, Xilinx Vivado HLS, R, PYNQ, MATLAB, FPGA, Arduino, Fusion360, AutoCAD, Android Studio, ANSYS, COMSOL, Python, C/C++, SQL, SCADA

- An excellent communicator, storyteller, and data visualizer

- PhD in Computer Science, Materials Science, or preferably both

I hate to be the bearer of bad news, but the person described in this job post, and ones like it, does not exist. And if they do, you’ll literally be competing against the most deep-pocketed companies in the world to hire them. (If you don’t believe me, go ahead and search for “battery data” on the Careers portal for Apple or Tesla.)

For companies seeking this talent, the unfortunate fact is that in the current market, experience and skills such as data engineering, web application development, cloud software operations (aka “DevOps”), data science, data visualization, and especially battery science / engineering / analysis are all in extremely high demand. Of course there are probably a few unicorns that combine some meaningful set of these qualifications, but you should assume that you’re not going to be able to find and hire them, at least not quickly. And you need this capability now.

So what’s a battery-powered business to do, when looking to incorporate ML/AI into its operations? There are a couple options:

Option zero: Hire that unicorn

We’ll keep this option up front here since so many companies are taking this approach. Having spoken to hundreds of companies in the battery ecosystem who have either tried to hire that unicorn engineer, or let existing engineers build their analytics infrastructure in-house with fractional time, we have a good sense of where you’re likely to end up if you pursue this option. Namely:

- ML/AI proof-of-concepts that may wow the execs, but in reality take months to show results with each new iteration, as engineers lose time on low-value tasks like searching for relevant data, cleaning it, and pairing it with the right set of tools. The result is a nice demo that is highly specific to the data it was trained on, but not generalizable or broadly useful to the business.

- Or a fragile, opaque, unmaintainable data infrastructure that only the engineers who wrote the code know how to use.

- Or both.

In the end, it’s no coincidence we’ve called this “Option zero”, as that’s the value we predict you’ll get by going this route.

Option one: Hire a team (not an individual)

The first “real” option is to build a team combining the necessary skills, namely data engineering, DevOps, data-intensive application development, and battery science (or electrochemistry, or materials science, or ideally all of the above). So instead of the one idealized battery data genius sought in your job post, you’re actually trying to recruit multiple highly sought after individuals with a diverse skill set. Plus you need someone in a project or product management role, to gather requirements, track schedules, iterate with end users, and so on. Note that this estimate is in line with a rule of thumb offered by Quantumscape CTO Tim Holme, who observed that in his experience it takes five data engineers to enable a single battery data scientist.

So let’s call it a team of five. Once salaries and benefits are factored in, you’re talking annual investment in the high six figures or low seven figures depending on where you hire. Also remember that it will likely take several months to assemble the full team, and at least a few more months to get them oriented in a new company, gather requirements, and design a system. Roughly speaking, you’re talking about a year and about a million dollars just to recruit staff and get your in-house battery analytics build rolling, before anyone has written a single line of code. When you factor in the several additional months (at least) before your custom-built system begins to deliver any user value, and ongoing support and maintenance over time as user needs evolve and data volumes grow, you’re looking at a multi-year, multi-million dollar commitment. Hiring contractors to do the same might save you a couple months, but will likely cost even more. (To learn more about this approach, including the true cost, fragility of internal systems and opportunity costs check out our Build vs. Buy eBook).

At this point you should ask yourself whether recruiting a new software team (when software is not your company’s core competency), and waiting a couple years for them to deliver results is the right move for your business. Even if you can afford to make the hires, can you afford to wait that long in a market that’s moving this quickly? Most can’t. So unless you’ve beaten the odds and found that unicorn, it’s time to look for another option.

Option two: Empower your data scientists with Enterprise Battery Intelligence™

While your business is no doubt unique, you are hardly alone in finding that data analytics infrastructure and tools are vital to success for your battery products and teams. Fortunately, a new category of software has emerged to address the needs of data-driven, battery-powered businesses, and it’s called Enterprise Battery Intelligence, or EBI. An EBI platform helps companies use data analytics to accelerate product development, secure high-quality battery supply, accelerate and optimize manufacturing, and minimize risk around batteries and battery-powered products.

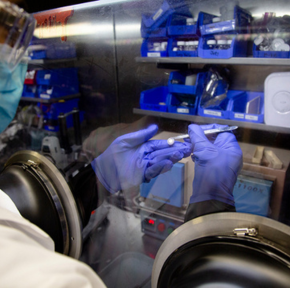

Perhaps more importantly, an EBI platform will automate 90% or more of the cumbersome, clerical tasks around gathering, cleaning, labeling, and featurizing battery data streams — all of the necessary prerequisites to using ML and AI to derive valuable insights from your data. Crucially, an EBI platform will have battery expertise and best practice built in — automatically extracting most of the parameters your team will need to power predictive models, with customizability to generate additional “special sauce” parameters that you develop as core intellectual property.

The bottom line is that an EBI platform replaces the need for those “five data engineers per data scientist” mentioned above. Because the battery expertise is already built in, going the EBi route also enables you to hire more general data science/ML/AI expertise, which you may already have in-house.

In functional terms, an EBI platform does all of those things you’re hoping your battery data unicorn will do for you, including:

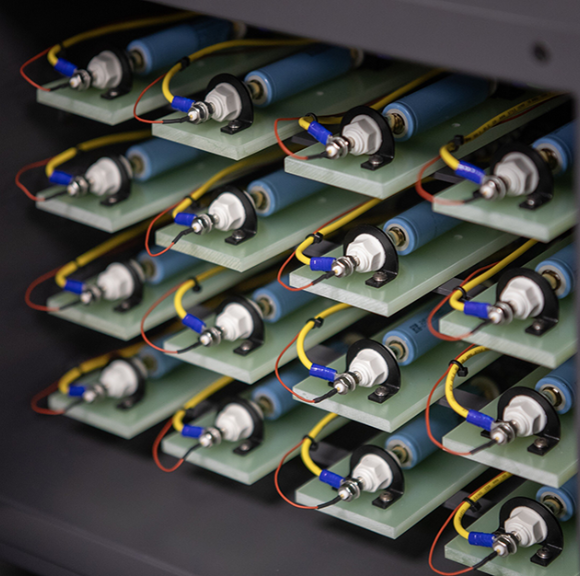

- Automate collection of battery data across the product lifecycle, from the test lab to the production line to field applications.

- Centralize data storage in a consistent, “harmonized” format, with browser-based access from anywhere.

- Extract key performance indicators (KPIs) and other data features from these data streams, that can power machine learning models of battery health, performance, and failure.

- Visualize and compare battery performance, from individual cells to large batches, with tools designed by and for battery engineers and scientists.

- Perform advanced analysis and KPI extraction for all industry-standard battery test protocols.

- Provide a programming environment (Python or MATLAB) directly in the platform for developing new intellectual property in the form of battery models and machine learning algorithms, using the performance data and advanced KPIs stored in the platform.

If time-to-value and total lifetime cost are key factors in your organization’s battery analytics initiative, empowering a data science team with an EBI solution is the shortest path to breakthrough insight.

Voltaiq is the EBI leader

Ten years ago my co-founder Tal Sholklapper and I recognized the need for enterprise-class analytics infrastructure across the battery ecosystem while leading teams developing new battery and electrification technologies. In 2012 we founded Voltaiq with a mission to accelerate the transition to a battery-powered world, and have since pioneered the EBI sector. Our customers find that the Voltaiq EBI platform empowers their battery teams to focus on high-value analysis tasks that drive product decisions and business success, rather than low-value tasks like manually collecting and formatting large amounts of raw data. Time savings of ten hours per engineer, per week, are typical. The enterprise-level benefits are even greater, as the system becomes a central, single source of truth for our customers, enabling remote teams to collaborate seamlessly and drive projects forward.

Most importantly, Voltaiq can begin delivering value within days of beginning your subscription, with new customer onboarding completed in less than a month. And as the best-in-class solution for the battery ecosystem, Voltaiq will help you recruit and retain battery talent, as the best people want to use the best tools.

Customers we can name here include leaders in the transportation sector (Mercedes-Benz, Proterra), the battery and battery materials supply chain (Sila Nanotechnologies, Albemarle, Anovion, C&D, Lyten), and, perhaps most notably, tech giants including Google, Amazon, Microsoft, and Meta. Speaking of software as a core competency, these are four of the most sophisticated tech companies in history, and all of them determined that empowering their teams with Voltaiq was a better option than building in-house (though a couple of them tried — and failed — to build an in-house system before bringing in Voltaiq). Do you think your company will have more success going it alone? It’s possible, but not likely. And you’ll need to find some unicorns.

In summary

If you’ve already recognized that the ability to extract data-driven battery insights will be crucial to your company’s success, then you’ve taken the necessary first step. If you’re determined, however, to address this need internally, starting with a unicorn hunt, then we’re here to tell you that realistically you’re looking at a couple years and a couple million dollars before seeing results. And all the while your competitors will continue to improve, and battery technology will continue to evolve.

If you’ve decided you’re not up for a unicorn hunt after all (or hiring a full software team, for that matter) and want to take a faster route to empowering your battery teams and charging up your battery programs, then you should look to bring in a commercial solution designed specifically for the battery ecosystem and the people that work in it. And Voltaiq is a great place to start.

Related Posts

The 2023 Battery Report

Battery Industry Trends: Key Insights and Trends from the Volta Foundation

Decoding the Heartbeat: Unlocking Battery Production Efficiency with Data

Subscribe to the Building Better Batteries Newsletter.

Written for battery engineers and leaders in the battery industry. Find resources, trends, and insights from some of the world's top battery experts.

-1.png)