Today’s parade of battery recall news is nothing new

Battery-driven recalls damage brand and balance sheet

There is an obvious barrier to realizing an electrified, battery-powered world, and anyone with a passing interest in the field knows what it is. Fire. Exploding laptops and phones. Combustible cars and headphones and hoverboards and home energy storage units. These adverse events have been happening for decades because no one has been able to sufficiently untangle the enormous complexity of battery systems. Not Amazon or Apple, Best Buy, Dell, Samsung, Microsoft, Nvidia, Panasonic, LG, or dozens of Fortune 500 companies. They’ve all implemented costly product recalls due to battery quality issues.

Such actions are hugely expensive. Sony recalled 9.6 million laptop batteries at a cost of $429 million. Ford recalled its Kuga plug-in for $400 million. Hyundai is spending an estimated $900 million to recall the Kona EV — roughly $11,000 per vehicle, making this the most expensive single-component vehicle recall in history. And just last week GM (again) recalled over 51,000 Bolt EVs. Even worse, such recalls can do long-term brand damage.

Think about when Samsung’s Galaxy Note phones were banned from airplanes — the company is still living with that. In the EV space, recalls are actually stunting growth. When early-adopter consumers are being told not to park a car in the garage because it might explode, that creates a lot of fear, uncertainty, and doubt for anyone considering going electric.

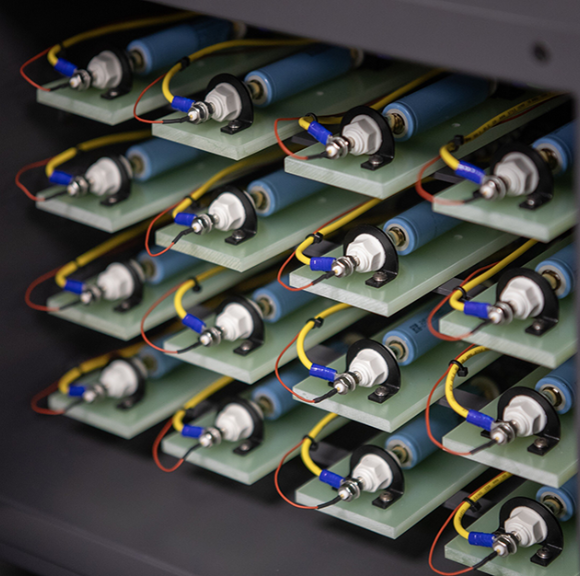

Why does this keep happening? Here’s the easy, unsatisfying answer: a lot of reasons. Highly charged (positive and negative) materials sit mere microns apart in a battery’s housing. When everything is properly aligned, the combination seems almost magical — providing silent, efficient, instantaneous power. But the smallest misalignment or minor abuse can cause the battery to suddenly release that energy all at once — and go boom!

Good engineering and process control can help, but when you look at the rapid expansion of production, materials innovation, and supply chain developments, there are bound to be problems. There are just so many unknown unknowns, and none of the old tools, systems, or skills apply. There’s a pressing need for a better data analysis infrastructure.

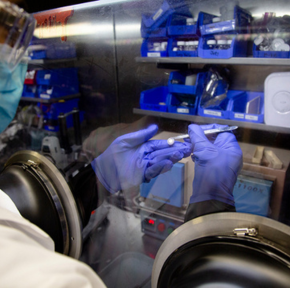

The Voltaiq Enterprise Battery Intelligence platform greatly reduces this risk. The platform sheds light on variations or misalignments — without having to open the battery — months or even years before they’re detectable through traditional methods. It’s almost akin to a CT scan or an MRI, laying bare the battery’s underlying chemistry during normal operation to identify cell degradation, conduct root-cause analysis, and perform competitor benchmarking.

Voltaiq does this by taking time-series charge and discharge data, combines it with analytics about the inner electrochemistry, and matches behavior against known profiles that can lead to failure. This capability is key for any company making an electrification push. If you can identify a faulty batch of batteries, that can make all the difference, whether that means hitting a product launch or avoiding a costly recall after you’ve gone to market. Your customers and shareholders will thank you.

Related Posts

How data makes your electric vehicle more valuable

Subscribe to the Building Better Batteries Newsletter.

Written for battery engineers and leaders in the battery industry. Find resources, trends, and insights from some of the world's top battery experts.