How to Make Money Manufacturing Batteries (And Why It’s So Hard) Part 3

Part 3: How To Properly Monetize Battery Manufacturing

In the last post, we discussed the technical and logistical challenges when building a gigafactory, and their impact on profitability. In this post, the final in the series, we’re going to discuss how to properly monetize battery manufacturing.

In presenting these many and daunting challenges to starting up a new battery factory, we by no means wish to discourage anyone. With global demand for battery cells skyrocketing, there is a massive and lucrative opportunity for companies that get it right — and many will. In this section we’ll lay out some keys to success for getting to full production scale quickly, and staying there profitably.

The key is speed!

As mentioned earlier, the primary lever to reaching profitability in battery manufacturing is getting to the self-funding point, and then to breakeven on the overall investment, as quickly as possible. But let’s break down what this means in practice.

In simple economic terms, breakeven means the total revenue on all the batteries you sell matches or exceeds the variable costs associated with making the cells (mostly materials inputs), plus the overhead of running the factory (people, utility service, building maintenance, etc.).

And how do you maximize profit? By making as many cells as possible with sufficient quality to sell them to someone else. Let’s again revisit the concepts of throughput and yield, the key drivers to battery manufacturing profitability.

- Throughput: The total number of battery cells you can produce in a given time period

- Yield: The percentage of manufactured cells that pass quality control and can be sold

These two are often intimately linked. As you refine your process to improve yield (and can thus make an increasing number of good cells relative to what you lose as scrap), you can ramp up throughput a bit while further refining the process to ensure yield is maintained. This process repeats iteratively on the path to full production.

Revenue (and thus profit) is ultimately a function of throughput multiplied by yield percentage. The challenge boils down to maximizing both throughput and yield simultaneously. If you run your production line at maximum speed, but have to scrap too many cells that fail quality control, your plant will not be profitable. Conversely, if you have great yield but have to slow down your production line to achieve it, you’ll again fall short. If you get both right, your cash flows will turn positive and stay there. Let’s have another look at one of our earlier charts to get a feel for how doing so directly impacts profitability.

On this chart, the path highlighted in green illustrates the potential benefits of accelerating production ramp, namely:

- Faster time to market, time to self-funding. The sooner you get yield up, the sooner you can actually start selling batteries. The faster you ramp throughput, the more revenue you’ll make.

- Greater profitability in the long run. Again, a higher yield means more saleable batteries, and thus more profit for a given production throughput. Happily, increasing yield also tends to increase throughput due to less overall downtime and time spent troubleshooting.

- Faster and larger return on investment. The area between the two curves represents the massive lost time, lost revenue, and increased expense that result from taking the default path (grey) as opposed to the optimized one (green).

And likewise, let’s take one more look at the more financially oriented chart to observe these impacts in terms of payback on investment.

Here you can see how ramping up throughput and yield faster gets you to self-funding and breakeven sooner, meaning you can raise less money for each factory, and enjoy greater profitability over the long run.

The key to speed? Enterprise Battery Intelligence!

You’ll see on these last two charts that the more optimal green path is labeled the “EBI-enabled path”. EBI here stands for Enterprise Battery Intelligence, an emerging category of data infrastructure and analytics software specifically targeted to helping battery-powered businesses achieve profitability and success in the marketplace.

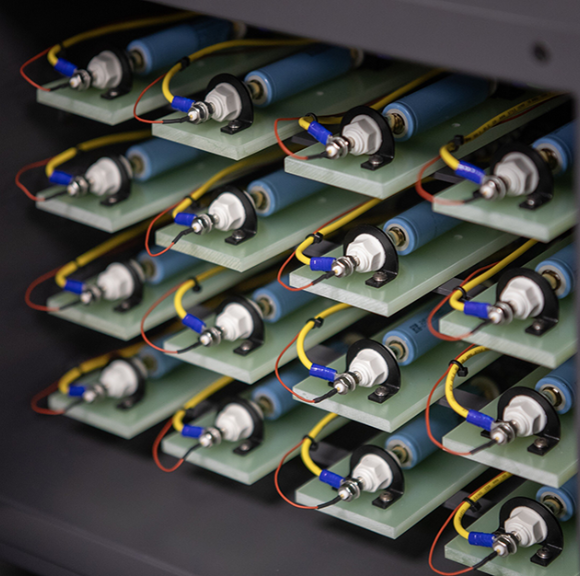

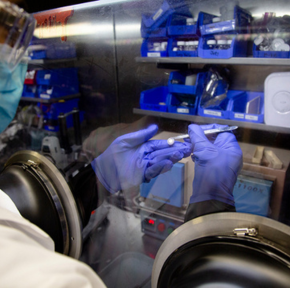

In a battery manufacturing setting, an EBI system provides an analytics layer that automatically aggregates data from across the production line — materials batches, equipment setpoints, formation cycling, and end-of-line quality control information — applying battery-specific analytics to make key correlations and actionable insights instantly available across your organization. This capability brings a range of benefits to a battery manufacturer.

- Accelerated production ramp by shortening the feedback loops between production runs. An EBI system can detect problems early in formation, and alert you to issues in real time. Correlations to materials and process information can quickly identify which parts of your recipe need fine tuning. You no longer have to wait days for formation to complete, or days longer to prepare all of the data for analysis — The key information is immediately at your fingertips, so you can iterate quickly and get to profitability faster.

- Improved yield. EBI analytics can use formation cycling data to derive much deeper insight into battery quality than the current industry-standard practice. To use a medical analogy, most formation cycling analysis amounts to measuring a battery’s height and weight (really its voltage and capacity). By contrast, EBI is like a cardiologist examining the battery’s charge-discharge “heartbeat” like a detailed EKG, identifying more nuanced clues as to how a battery will perform over the long term. Over time, these insights can be used to further optimize your production process to drive even higher yields than the base case would permit.

- Faster response to production issues. Production issues will inevitably arise. EBI can alert you quickly to end-of-line quality problems, and facilitate rapid root-cause analysis through its materials and process tracking functionality to get you back up to full throughput and yield faster. EBI can also help you avoid recalls by detecting issues before faulty batteries find their way into customer hands. In the unfortunate event that you do need to recall product, EBI can help you limit the scope of any recall by isolating the problem to the affected batches or production lines.

An EBI system will integrate with and run alongside your existing tooling (MES, formation data capture, etc.) so that you can be up and running quickly, iterating toward success. Ultimately, this level of data agility and depth of analysis is a table-stakes requirement for any company that manufactures batteries today, or plans to in the near future. As the company that pioneered EBI, Voltaiq is proud to work with a number of companies at various stages along this battery manufacturing journey. We’d love to learn about your challenges and see if we can help. Give us a call!

Related Posts

The 2023 Battery Report

Battery Industry Trends: Key Insights and Trends from the Volta Foundation

Decoding the Heartbeat: Unlocking Battery Production Efficiency with Data

Subscribe to the Building Better Batteries Newsletter.

Written for battery engineers and leaders in the battery industry. Find resources, trends, and insights from some of the world's top battery experts.