How to Make Money Manufacturing Batteries (And Why It’s So Hard) Part 2

Part 2: Challenges When Building a Gigafactory

In our first post, we detailed the high-level financial drivers when trying to manufacture batteries profitably. In this post, we’re going to dive into the technical and logistical challenges when building a gigafactory, and how they impact profitability.

Why is it so hard to make money manufacturing batteries?

Getting to profitability in battery manufacturing is a multi-stage challenge, from actually building the factory, to ramping production up to a profitable level of throughput and yield, to maintaining quality and profitability over the long run. (For some background reading on this topic, see our previous post “So you want to build a battery factory”.)

Building the factory

The fun begins the day you start building your battery factory. Here are some of the biggest challenges you’re likely to encounter:

- Sourcing equipment: With 90% of anticipated battery manufacturing capacity yet to be built, it’s no surprise that the production equipment to fill all those factories will be in short supply. Unlike other more mature high-tech manufacturing sectors like semiconductors or pharmaceuticals, production equipment for advanced lithium-ion battery manufacturing continues to evolve rapidly. New production techniques driven by innovative cell designs or processing steps mean that your equipment may not exist and will need to be custom-built. The supply base for this equipment is highly varied as well, comprising a mix of multinational industrial companies and mom and pop outfits. Like many other industries, the global Covid-related supply disruptions have impacted this sector as well. The bottom line is it will likely take over a year just to equip your factory.

- Sourcing materials: In addition to production equipment, of course you also need the materials to make the batteries themselves. If you’re planning to start production any time in the next couple of years, you should already have your materials supply locked in by now. With global production increasing sixfold over the next several years, you should assume that materials supply is going to tighten accordingly. Add in complications around geographic concentration around sourcing and processing of key materials, geopolitical instability, and ethical sourcing concerns, securing a steady supply of high-quality materials for your factory is an enormous challenge in and of itself.

- Sourcing talent: Let’s assume you’ve locked in supply lines for your production equipment and materials. Who is going to run your plant? A future with six times the global battery production will require roughly six times the number of people working in battery manufacturing today. It is safe to say that those people don’t exist yet, or more precisely they haven’t been trained and lack the experience needed to spin up a battery factory and keep it running. Indeed, at a recent battery manufacturing panel at The 2022 International Battery Seminar, the consensus across the panel of experts was that finding people would end up being the biggest challenge in getting a new gigafactory up and running. The key takeaways here are that 1) you will need to look more broadly for talent — food manufacturing and pharmaceuticals have been mentioned as potential sources, and 2) you need to equip your people with force-multiplier tools that will make them maximally productive and effective.

Ramping up the factory

When we talk about “ramping up” a battery factory, we’re referring to the process of starting up production lines, fine-tuning your production process using limited production runs in pursuit of your yield target, and then increasing production until you reach the point where your factory is profitable on a per-unit-manufactured basis (the “self-funding point”). The following chart provides an illustration.

This chart illustrates the link between ramping up manufacturing capability and the investment payback timeline shown in the earlier chart. Winning in battery manufacturing is all about getting the combination of throughput (number of units you make) and yield (percentage of production that passes quality control and can be sold to customers) to a profitable state as quickly as possible. Even once your factory is fully built and equipped, this process can still take years as illustrated by the Panasonic and LG cases mentioned above. Here are some of the key challenges you’ll face:

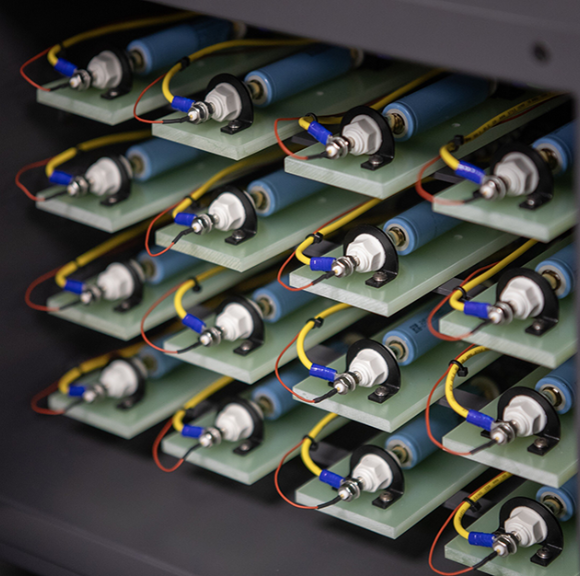

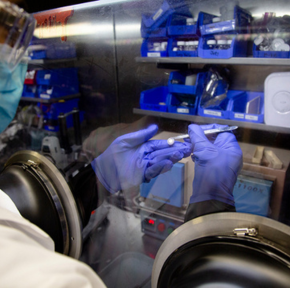

- Battery manufacturing is complicated: At a high level, battery manufacturing comprises three main stages — electrode fabrication, cell assembly, and end-of-line. However each of these stages comprises dozens of individual steps, and hundreds (if not more) of equipment settings: speeds, temperatures, pressures, and so on. Achieving profitable production throughput and yield requires precise orchestration of all of these parameters into a recipe that will produce a commercially viable battery. It’s just plain hard to get all of it right and can literally take years of iteration when bringing up a new factory. This challenge is compounded when building a factory to support the latest and greatest cell technologies — which by definition have not yet been mass produced.

- Cycle times are slow: When running at full speed, it only takes a handful of hours for a production line to transform a batch of raw materials into a fully assembled battery. However, it actually takes days or weeks longer to determine if that battery is any good. This delay comes down to two final steps in the manufacturing and quality control process, formation and aging, commonly known as “end-of-line”. Formation cycling (a.k.a. “formation”) is the slow, careful charging and discharging of a finished battery cell over a handful of cycles to form and lock in the vital internal structures and interfaces that ensure the cell’s performance and longevity. Each and every battery cell goes through formation cycling, and the process typically takes a few days. Formation is also the first time the battery produces any sort of electrochemical data, and as such is really the first opportunity to tell for sure if the cell is any good. Thus, when ramping up a new factory, formation necessarily implies that the minimum feedback cycle time for any tweaks to your production recipe is at least three or four days, realistically more like a week. But it gets worse. After formation, a cell goes through “aging” in which newly produced cells are stored in a warehouse for anywhere from a week to a month, after which each cell’s voltage is measured and compared to its voltage when it finished formation. If a cell’s voltage declines too much during this aging period, there is some undesirable self-discharge taking place (an internal short or similar) and that cell is rejected by quality control. A longer aging period indicates more rigor in the quality control function of a battery manufacturer, however the tradeoff is further extending the feedback cycle needed to determine if a given production recipe will produce the desired results.

- Systems are immature: Manufacturing lithium ion batteries at the scale currently being planned really is unprecedented, and as such a lot of best practices are still being figured out in real time. One implication of this immaturity is that the computer systems that link together all the equipment in a factory and record process parameters and similar continue to be in a developing state. Many of these Enterprise Resource Planning (ERP), Manufacturing Execution Systems (MES), and Product Lifecycle Management (PLM) software packages are custom-built, or adapted from other industries, and may or may not be capturing the most useful and relevant information from the production line. Even less mature are the tools that are used to analyze all of the data coming from the production line, formation, and aging to determine what makes a good cell and ultimately increase production and optimize yield. It can take weeks or longer just to analyze all of the data from a production run, connect the dots across multiple disparate systems, and determine what to try next. When combined with the delays inherent to formation and aging, production iteration cycles can stretch to several weeks.

In light of these challenges, most notably iteration cycles denominated in months and not days or weeks, it is actually not that hard to understand why it can take multiple years to ramp up a new factory to full production. These challenges also put in perspective the ambitious timelines being proposed by new entrants who plan to fully ramp up in a year or less. We hope they’re right, but in all likelihood it will take substantially longer.

Running in steady state

If you get to the point where your primary concern is running a battery factory at steady state in full production capacity, then congratulations are in order! You have overcome a multitude of major obstacles that continue to trip up some of the most experienced companies in the field. You’ll still be faced with the ongoing challenges of continuing to source an adequate supply of high-quality materials, and retain enough experienced staff and institutional knowledge to keep things running smoothly in an extremely tight market for battery expertise. But if you’ve come this far, you probably have a good handle on those things as well.

Production issues will inevitably arise, however. And when they do, those same issues around immature and inadequate data and analytics systems can severely hamper root-cause analysis and lengthen response times. Both of these can be disastrous to your cash position when running a high-volume, commodity manufacturing business, particularly if you have to stop production or recall batteries. Having access to the best modern tools for gathering and analyzing all of this data, from mixing slurries through to formation and aging, is ultimately vital to dispatching production issues quickly and resuming profitable operation.

In this post, we detailed the technical and logistical challenges when building a gigafactory, and their impact on profitability. In our third and final post, we’re going to discuss how to properly monetize battery manufacturing.

Related Posts

The 2023 Battery Report

Battery Industry Trends: Key Insights and Trends from the Volta Foundation

Decoding the Heartbeat: Unlocking Battery Production Efficiency with Data

Subscribe to the Building Better Batteries Newsletter.

Written for battery engineers and leaders in the battery industry. Find resources, trends, and insights from some of the world's top battery experts.

-1.png)