In a recent webinar, we gathered together a panel of gigafactory veterans to explore the lessons they’d learned working on the front lines of battery manufacturing. Alongside Voltaiq co-founders Eli Leland and Tal Sholklapper, we were delighted to talk with Tony Thai, former gigafactory production engineer, now a Senior Battery Engineer at Voltaiq; and Wilbert Kemp, former gigafactory senior quality engineer, now leader of our platform quality and operations team.

We explored the challenges and intricacies of battery production at giga-scale, ranging across topics such as production speed, supplier relationships, and more. Here, we distill a quick overview of the key insights shared. For a comprehensive understanding, we recommend watching the full session. Otherwise, read on for the main takeaways.

1. Balancing Speed and Quality Is a Tightrope

Like all battery manufacturers, gigafactories want to maximize production speed without compromising quality. There is a constant imperative to streamline processes for increased throughput, reduce costs through improved yields (which produce less scrap waste) and supply chain management – all while ensuring compliance and upholding safety standards.

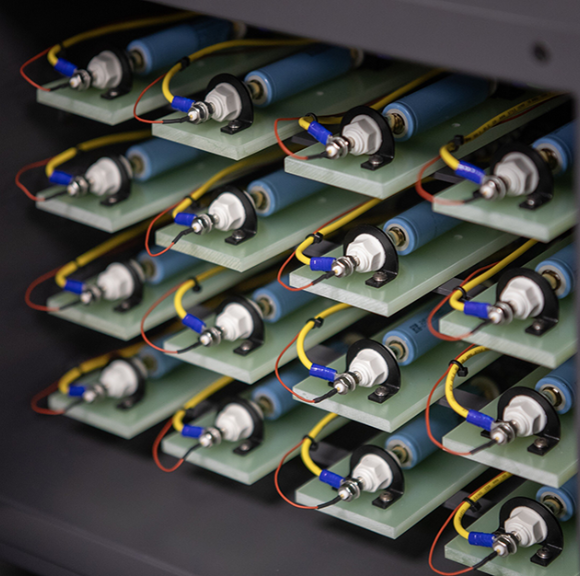

A gigafactory’s complexity makes finding this balance harder than ever. Unlike simpler production facilities, a gigafactory consists of three main sections: electrode fabrication, cell assembly, and formation and quality assurance (QA). This complexity leads to challenges in identifying and addressing issues that may arise in one area but only become apparent in later stages, highlighting the importance of effective communication and collaboration among departments.

In a gigafactory, the manufacturing process involves a coordinated effort among various teams to ensure the right equipment, materials, labor, and knowledge are in place. These teams are organized into four key pillars: supply chain, quality, engineering, and production. Each pillar has a distinct role, from sourcing materials and ensuring quality standards to troubleshooting and managing day-to-day operations.

Optimizing the interaction between these pillars is the only way to balance efficiency with quality – but it isn’t easy.

2. Managing Large Teams Requires Great Skill

One of the most daunting aspects of running a gigafactory is coordinating a vast team towards a common goal. When everything is running smoothly, it’s a rewarding experience. However, when production problems arise, aligning thousands of individuals can become a logistical challenge.

Difficult days often manifest in two ways: the need to pivot quickly or the frustration of gridlock. The latter can be particularly trying, with a “hurry up and wait” dynamic that tests patience and efficiency. Additionally, the nature of continuous improvement means there are always issues to address. Prioritizing these issues is a daunting task, made even more difficult by the fact that overlooked problems can often be the most impactful.

Conflicts between production and quality teams are common, each driven by different priorities. Production focuses on numbers and ramping up, while quality aims to prevent defects from slipping through during these periods of increased activity. Resolving these conflicts often boils down to effective communication and understanding each other’s needs and constraints.

For instance, a simple solution like placing a placard on a shut-down machine with the reason, necessary actions, and estimated time for resolution can prevent misunderstandings and reduce tension. The balance between productivity and quality is crucial, underscoring the need for realistic planning and patience in the complex landscape of large-scale manufacturing.

3. Solve Boring Problems (Not Just Interesting Problems)

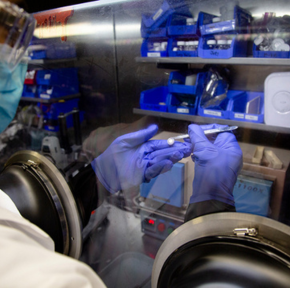

In manufacturing, problems can be categorized into two types: exciting and boring. The exciting problems, such as slurry rheology and coating thickness, often capture the attention of engineers due to the allure of their complexity. However, it’s the boring problems, like oven maintenance and cleaning, that are frequently overlooked despite their significant impact on the production process.

Take, for example, the issue of metal contamination in battery manufacturing. During the process, metallic electrode substrate films are slit and rolls are cut, creating numerous opportunities for burrs and particles to form. One might assume that the primary focus should be on the winding process of winders, as it is their main function. However, a less obvious but equally important aspect is the cutting of the substrate. If the blade is not sharp enough, it can generate tiny metal particles that are invisible to the naked eye. These particles can then be wound into the jelly roll of the battery, leading to failure in later stages of production — or even internal short circuits resulting in disastrous fires months or years later once products are in customer hands.

Addressing this issue requires a shift in focus to the mundane yet crucial task of cleanliness. By inspecting each winder and wiping them down as needed, a factory can prevent the recurrence of this problem, potentially saving millions of dollars. This approach also allows for a straightforward calculation of the return on investment by comparing winders with and without the cleaning protocol, thereby quantifying the impact of cleanliness on the overall process.

Though this isn’t the most exciting or intellectually stimulating of challenges, it’s critical that gigafactory workers focus on everything, even (or especially!) cleaning and maintenance, to get the plant running as well as possible.

4. Outlier Cells Must Be Investigated

In a gigafactory, the quality team plays a crucial role in determining whether cells are fit for shipping. The line has upper and lower specifications for factors like voltage, internal resistance, and capacity. Cells that fall outside these specs are typically rejected. However, towards the end of the manufacturing process, it’s not just about identifying cells that barely miss the mark; it’s also about spotting those that are significant outliers.

These outliers are particularly interesting because they can indicate underlying problems in the manufacturing process. For example, a cell with an unusually low capacity might have a large U-shaped defect in the cathode, suggesting a serious issue that needs to be addressed. While such defects might occur infrequently, their presence can be a symptom of a larger problem that could potentially worsen over time.

High internal resistance is another red flag. It often points to issues like improper tab welding or insufficient contact between the cell’s innards and the can. Identifying these defects is critical because they can bypass checks upstream in the manufacturing process. By focusing on these extreme outliers, the quality team can ensure that potential problems are caught and addressed before they become more widespread, ultimately ensuring the reliability and safety of the batteries produced.

5. It’s Tempting to Sacrifice Improvement for Stability

In every gigafactory, there is a constant tug-of-war between maintaining stability and seeking continuous improvement. On one side, there’s the argument to let the “golden goose” keep laying eggs without interference. On the other, there’s the push to make the goose lay eggs faster. The decision to run at steady state versus optimizing the process depends on the cost-benefit analysis of any proposed changes.

For example, spending an exorbitant amount to marginally increase machine speed may not be justifiable. However, a low-cost improvement, such as regular cleaning to reduce defects, can provide significant benefits. The key to making informed decisions lies in having comprehensive data about the process.

Most factories have vast amounts of data collected by programmable logic controllers (PLCs) connected to process equipment, but this data is often underutilized until a problem arises. By analyzing this data throughout production, factories can make data-driven arguments for or against specific improvements, calculating the return on investment for each proposal. Maintaining a steady state while continuously improving requires a delicate balance; the goal is to keep the factory in a stable equilibrium, producing high-quality products at high volumes while carefully evaluating and implementing improvements based on data-driven insights.

6. Proprietary Information Needs to Be Handled with Great Care

Negotiations with customers can become complex when proprietary information is involved. There are instances where a customer might request specific drawings or data in exchange for assistance or resources. However, sharing such information can be risky, as it might lead to the customer independently replicating processes or components. As a result, manufacturers often have to find alternative solutions to satisfy customer needs without compromising their intellectual property.

At the engineering and management level, the exchange of information is usually a careful give-and-take. While certain data, like in-field charging or car testing results, can be shared to mutual benefit, more sensitive information should be kept internal. For example, specific metrics used for internal quality control, such as self-discharge rates or capacity between certain voltages, might not be shared with the customer. These metrics can be difficult to interpret without proper context and might cause unnecessary concern if shared externally.

This distinction between internal and external specifications is not about hiding information but rather about ensuring that the data shared is relevant and understandable to the recipient.

Get More Insights in the Webinar

The insights shared during our webinar provide a fascinating glimpse into the complexities of battery manufacturing. The challenges of scaling up production, ensuring quality, managing supply chains, and driving innovation are significant. However, with skilled and committed professionals, the future of battery manufacturing is in capable hands. For those interested in exploring these topics further, the full webinar provides a wealth of knowledge and firsthand experiences from industry veterans.

Related Posts

The 2023 Battery Report

Battery Industry Trends: Key Insights and Trends from the Volta Foundation

Decoding the Heartbeat: Unlocking Battery Production Efficiency with Data

Subscribe to the Building Better Batteries Newsletter.

Written for battery engineers and leaders in the battery industry. Find resources, trends, and insights from some of the world's top battery experts.

-1.png)